I quickly learned that it takes more than just a Cobra Body mold to be in the business of building these cars! My friend Kim dropped off an old Jig Table he had rusting away in his backyard..."You can use this more than me." he said. Double-click on the pics to get the full size.

I quickly learned that it takes more than just a Cobra Body mold to be in the business of building these cars! My friend Kim dropped off an old Jig Table he had rusting away in his backyard..."You can use this more than me." he said. Double-click on the pics to get the full size.My Dad's car finally was certified with the understanding that I never bring them another Frame like that to them again! Well, it was actually built on spec to a well-known USA-based Cobra Shop...I won't say which one.

Well, I now needed to design my own Chassis...but what type? Rectangular or Round Tube, Platform, Multi-tube or Backbone? Too many choices...all kinds being offered in the industry, where would mine fit in? I had a lot of complaints from guys over 6-foot tall that the Cobra was Uncomfortable and difficult to drive safely, so an idea was born. Why not drop the seating area down to the bottom of the frame rail...I could gain 3-inches depth right there. A lot of the manufacturers in the USA were actually altering the body shape to do this...That was not an Option here! Simply dropping the floor section around the pedals was also 'Cheesy' and unacceptable. It seems that my idea may be a good one...and it was! The picture above shows our first generation frame with dropped Steel Floor Pans and Welded Aluminum Foot Boxes. Although functional, this Frame still needed some work...

Well, I now needed to design my own Chassis...but what type? Rectangular or Round Tube, Platform, Multi-tube or Backbone? Too many choices...all kinds being offered in the industry, where would mine fit in? I had a lot of complaints from guys over 6-foot tall that the Cobra was Uncomfortable and difficult to drive safely, so an idea was born. Why not drop the seating area down to the bottom of the frame rail...I could gain 3-inches depth right there. A lot of the manufacturers in the USA were actually altering the body shape to do this...That was not an Option here! Simply dropping the floor section around the pedals was also 'Cheesy' and unacceptable. It seems that my idea may be a good one...and it was! The picture above shows our first generation frame with dropped Steel Floor Pans and Welded Aluminum Foot Boxes. Although functional, this Frame still needed some work...

The second generation was more streamlined and offered a custom-designed IRS as well. Instead of the welded Foot Boxes we now went with formed Rivet-on Aluminum Panels and Floor Pans...Much Better!

The end result was a Nice Looking, Rigid and Light Weight Frame and our Customers loved it!I also pride myself in claiming an original design. I did not need to copy anyone's design and call it my own, like so many of the other guys do that I came across.

The shop is starting to look like a real Production now, Customers, Prospects, Enthusiast and Friends dropping by regularly...it's a real 'Guy Hang-Out' now! A few Articles, Write-ups, Car Shows and most important of all 'Word of Mouth' are starting to produce results. Our Cars are cleaning up at the shows in both Canada and the USA.

Our reputation was beginning to grow...Affordable, Authentic, Detailed, Innovative, Handled...

The cars just 'Looked' and 'Felt' right!Tania had quit her job to retire at our Cobra Shop, running errands, answering the phone and chatting with our patrons! We stayed in Langley for about 6 Years and then decided to move the operation to Chilliwack, onto our own property and a much Larger shop. I could now spend more time 'playing' around with the cars. But then,

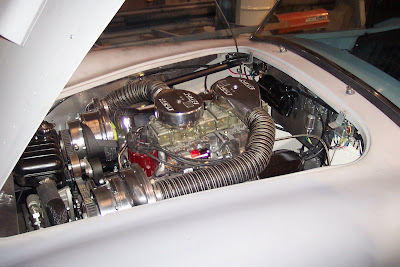

If it works, then don't change it, Right?Not around here! Not being quite satisfied with what we are using, I needed to make the car just a little more authentic and changed the upper tubular structure, exposed the Rollbar fully and tooled up some Fiberglass Foot Boxes. The IRS also got the treatment and now looked and worked more like the real thing! Most of our customers were now demanding 427 and 428 Engines, Pin-Drive Wheels, IRS Suspension and Original Cobra parts. This newly-engineered Chassis really did the trick! We now had a truly unique and sought after Kit. We tested the system repeatedly with 600-700 HP Engines, 514, 488 FE Strokers, Twin-Blown 427 and the list goes on. All held together at the brutality of the Owners heavy Feet...

.jpeg)

I have always worked on my own in our shop. It was easier to control the quality of the work and I didn't have to babysit employees...or I would have ended up behind a desk and managing a business. I decided I needed to work my business instead. This was not without consequence, I was working 10-12 hour days and mostly 7 days a week. Burn-out was just around the corner...

No comments:

Post a Comment